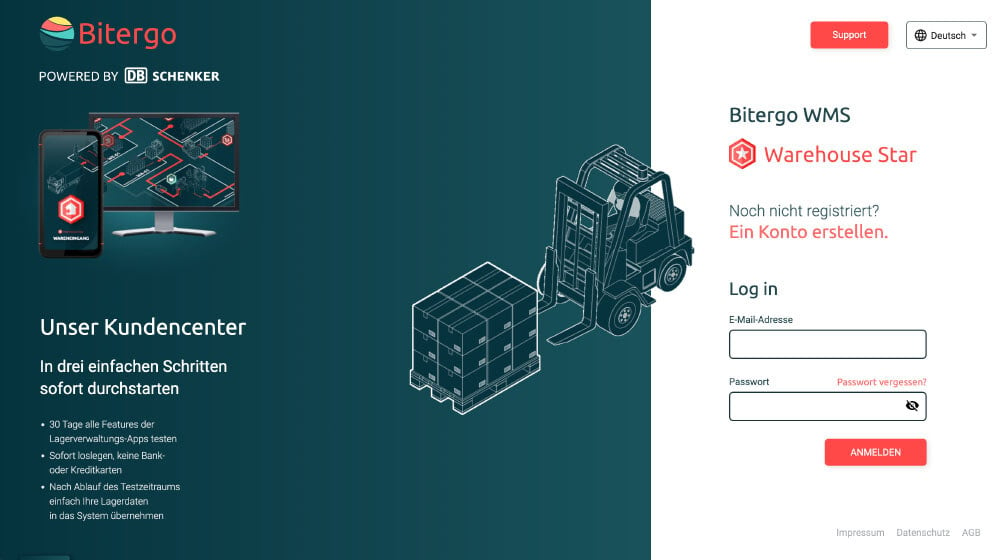

Bitergo WMS

Warehouse Management System from the Cloud for effective Processes in your Warehouse

- Ready to go within a few days

- Ready for the future: Grows with your needs

- Server located in Germany

- Free 30 days trial

Digitized Warehouse Operations! But how?

Are you struggling with similar challenges in your warehouse?

Are you tired of dealing with constant stock shortages in your warehouse? Do new or changing loan workers from day to day make it difficult to maintain performance and time constraints? Are outdated and error-prone Excel spreadsheets holding back your warehouse management?

Do you struggle to keep your online shop up-to-date with real-time inventory tracking? Or are you looking to open a new location at short notice? Is your business affected by seasonal fluctuations?

Are you eager to digitize your warehouse operations but worry that it'll become an overwhelming and costly project.? Are you intimidated by the complexity of integrating a software solution and the potential long learning curve for your employees?

More Efficiency, more Productivity

Bitergo WMS streamlines warehouse operations, increasing efficiency and productivity. Because Bitergo WMS digitalizes every step of your warehouse operations.

From setting up and managing your inventory and stock, through receiving goods and handling internal warehouse processes, order processing and fulfillment, packaging, shipping, and outbound logistics.

Get productive quickly and easily

Bitergo WMS enables you to digitize your entire warehouse in just a few days, making it an ideal solution for start-ups and small to medium-sized enterprises looking to streamline their logistics.

Bitergo WMS is

suited for:

- small and medium-sized warehouses,

- third-party logistics providers,

- e-commerce retailers and

- for the warehouses of manufacturing companies

Grows

with you:

With integrations to popular e-commerce platforms and ERP systems, Bitergo WMS enables streamlined workflows. As your business grows, our modular app ecosystem can adapt and evolve to meet changing needs.

One Solution for all

warehouse types:

Bitergo WMS supports all common warehouse types operated by workers and forklift drivers using mobile barcode scanners. Additionally, Bitergo WMS can be used in conjunction with automated systems such as conveyor belts, storage and retrieval machines.

The Bitergo WMS Suite

Functions and Features

- ASN (Advanced Shipping Notice) processing

- Support for any load carrier type

- Batch & serial number management for handling units

- Implementation of storage strategies that can be configured with regard to physical restrictions (height, weight, ...) or logical restrictions (item value, dangerous goods classification, ABC analysis)

- Efficient order picking processing (single order, multiple order, batch) taking into account different storage principles such as FIFO (First-In First-Out) or "Take the whole pallet

- Storage of items in a cross-dock terminal, a standard warehouse or a bonded warehouse

- Support for different scanning and identification methods: Handling unit label, EAN or location barcode

- Picking and packing, printing of transport labels

- Scan consignment units for completeness, measure weight, print delivery note

- Permanent inventory counting and electronic stocktaking

Bitergo WMS Suite Structure

Bitergo WMS consists of WMS Core, WMS Processes and WMS Utilities.

WMS Core provides the necessary tools for setting up and optimizing the configuration of your warehouse. WMS Processes maps the main processes of your warehouse operations and WMS Utilities maps all the secondary processes that ensure smooth warehouse operations.

WMS Core |

|

|

|

WMS Processes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WMS Utilities |

|

|

|

|

|

|

|

|

|

|

|

WMS Core

Bitergo WMS is a cloud-based WMS system. All you need to use it is an internet connection, one or more PC workstations with a web browser, and Android smartphones or barcode scanners for the warehouse.

Bitergo operates its servers exclusively in a German business cloud, ensuring the highest level of data protection for your information and that of your clients.

Bitergo WMS is continuously developed and updated, with these enhancements made available to our customers at no additional cost without disrupting their operations.

Bitergo WMS enables precise, valid, and simple entry and maintenance of your master data (article, warehouse structure, storage location, loading equipment, and partner master data).

All data can be entered either via an EDI interface, CSV import, or manually through the web-based interface.

Bitergo WMS supports the configuration of profiles for different task areas, ensuring that each employee only has access to the functions necessary for their job.

Bitergo WMS also supports multilingualism (German, English, Polish), with the option to set a unique UI language for each user. Additional languages can be integrated as needed.

Find out more about the Master Data App

WMS Processes

Bitergo WMS meets all requirements for efficient and optimized warehouse logistics.

Receiving Goods

Bitergo WMS enables quick registering of incoming goods. Handling units can be created against an advanced shipping notification or spontaneously. Barcode scanning, label printing, and creating pallet labels are supported. An advance shipping notification (ASN) can be received via the BSB interface from the ERP system or imported as an Excel/CSV file.

Find out more about the

Incoming Goods App

Storage

Bitergo WMS offers storage strategies for different warehouse types, such as block storage, rack storage or high-bay storage. In addition, specific restrictions are supported, such as pallet size, weight, fixed location assignments and/or freely definable classifications (e.g. ABC). Storage takes place in real-time using a mobile barcode scanner.

Find out more about the

Storage App

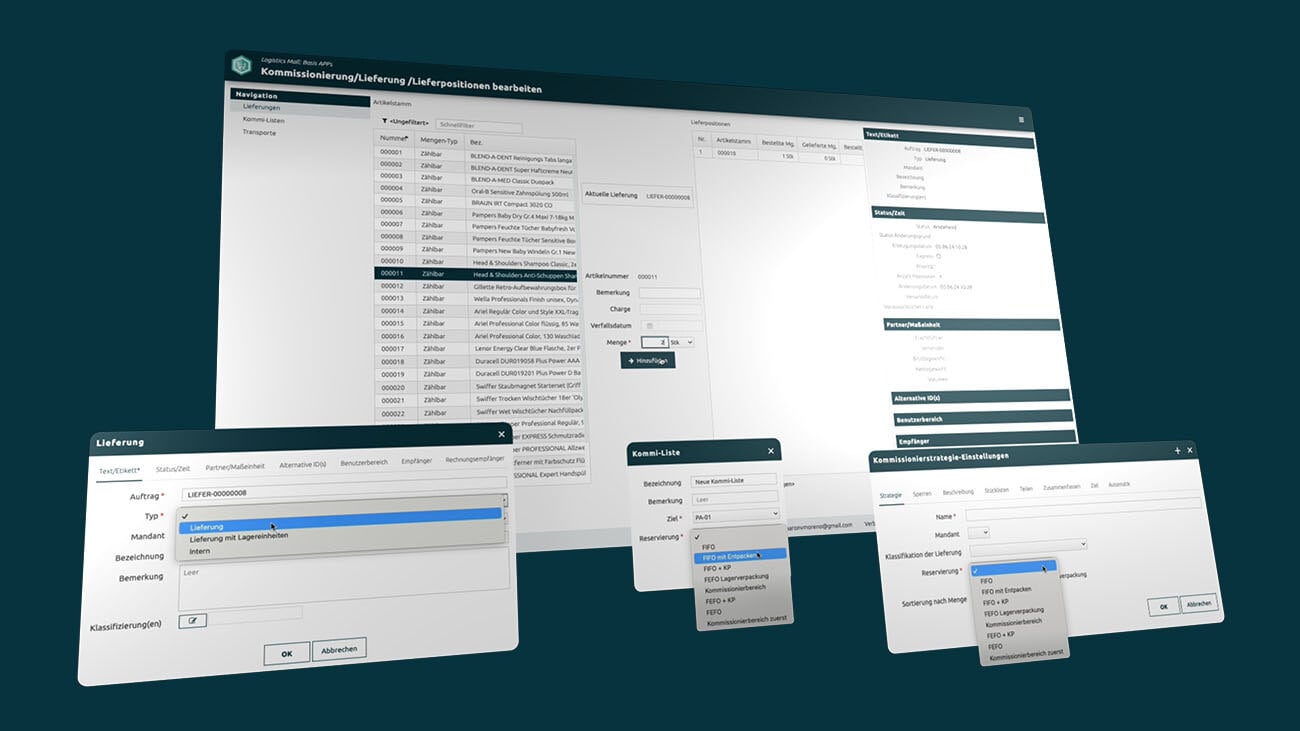

Order Management

Dispatch orders are received via a standard interface and displayed in the WMS. Next, the warehouse manager activates an order batch and creates pick lists for it. Bitergo WMS supports various strategies for this task, e.g. FIFO (First-In First-Out), expiry date, full pallet, multiple order, single order, single or two-stage, and offers a high degree of flexibility in controlling the picking process.

Picking

Bitergo WMS guides the warehouse worker via a mobile app along the shortest route to the storage location and records the removal of items in real time by scanning storage location and/or item barcode labels. Item changes, replenishment and the consideration of unexpectedly empty locations enable extremely precise warehouse management. Picking ends at a packing or despatch station.

Find out more about the

Order Picking App

Packing

Bitergo WMS supports the packing of picked items into one or more shipping units. Pick & Pack and various workstation configurations with connected printers and scales are supported.

Find out more about the

Packaging App

Outgoing Goods

Bitergo WMS helps you finalize the shipping units by supporting the printing of parcel labels and delivery notes. Optionally, shipping providers (e.g. DHL, UPS, Shipit Smarter, etc.) can be connected.

Find out more about the

Outgoing Goods App

WMS Utilities

Bitergo WMS offers a range of utilities for ensuring the smooth operation, optimizing your processes, and efficiently handling everyday challenges in your warehouse!

Information

Find the location of each item with just one click, saving your team in the warehouse from lengthy searches. Prevent space constraints or excessive unused storage space in time. With the clear display of storage locations and units, you can estimate and counteract your storage capacity at any time.

Find out more about the

Information App

Inventory Counting

Bitergo WMS enables electronic stocktaking and counting. This makes stocktaking processes simple, fast and minimises errors. Inventory management provides inventory reports in real time.

Find out more about the

Inventory Counting App

Corrections

A grab for the item, a new entry - Bitergo WMS enables direct adjustments in the system. Incorrect quantities? No problem, correct them immediately and assign every item to the right client. Every adjustment requires a comment. This way, you always have an overview and know why a change was made.

Find out more about the

Corrections App

Stock Transfer

There are always reasons to move goods. With Bitergo WMS, your goods can always be found. Stock transfer orders created directly in the mobile app or in upstream processes are processed by your employees in the warehouse and the new storage location is booked in the system after completion. This gives you full transparency of all goods movements at all times.

Find out more about the

Stock Transfer App

Repacking

Bitergo WMS offers you flexibility in the utilisation of your storage space. Storage units can be split up or merged. By scanning the source and destination, the data is immediately updated in the system and you can always keep your pallets organised.

Find out more about the

Repacking App

Reporting

With Bitergo WMS you can monitor and control performance, stock, and operations at a glance! Analyze changes and bottlenecks within the business. Accelerate business outcomes by increasing agility and efficiency in every area of operations. Efficiently use the information contained in your WMS' data to drive innovation, accelerate value creation, and increase your competitive advantage.

Find out more about the

Reporting App

Integrations

We have a variety of integration options that make it easy to link shipping companies, e-commerce platforms and ERP-systems.

If you want to develop your own code, we also have an open API.

Automated reusable load carriers management

The integration of the Logistikbude partner solution in Bitergo WMS enables automated management of all types of reusable load carriers like pallets, mesh boxes, containers, racks, IBCs and everything that is used between companies.

The administration of reusable objects requires a lot of personnel due to bookings, reconciliation and collection of data. Shrinkage and slow turnaround times result in high costs in the form of repurchase and capital commitment.

By using our Logitstikbude integration, you can:

- Reduce costs and optimize your stock of reusable load carriers:

Standardised load carriers are managed in terms of quantity and thus enable transparent exchange between all partners.

- Always keep track of your load carriers:

Individual load carriers receive a unique serial number and are tracked via barcodes, RFID tags or IoT trackers.

Learn more about the Logistikbude integration...

Test all features of Bitergo WMS for 30 days

Create a free account and test all apps and features! Play through our first steps tutorial!

Bitergo WMS Academy

In our WMS Academy we provide you with extensive material to support you in using our Warehouse Management System, such as our “First Steps Tutorial”, the user documentation, as well as helpful background information on Bitergo WMS.

Your first steps with mit Bitergo WMS – Warehouse Star

This tutorial is designed to give you a first impression of the most important apps and functions of Bitergo WMS / Warehouse Star.

You'll learn how to book an upcoming delivery into the receiving area, store the delivered goods, process an order by creating a picking list, commission the goods, pack the order, and finally prepare the shipment-ready goods for dispatch!

Master Data Web App

Incoming Goods Web App

Incoming Goods mobile App

Storage Mobile App

Picking Web App

Picking Mobile App

Packing Web App

Outgoing Goods Web App

Bitergo WMS in Action

Bitergo WMS in Stuttgart

Bitergo WMS Tour

References

"We have been using the Bitergo apps for over 4 years to optimize the processes in our warehouse. All processes - from goods receipt, storage and picking to goods issue - are handled with the help of the apps. We can track stock levels and goods movements at all times, which leads to significantly faster order processing. We are really very satisfied with Warehouse Star."

Jürgen Nehmer

Spedition Nüllig & Haß OHG

FAQ

Which warehouse types does Bitergo WMS support?

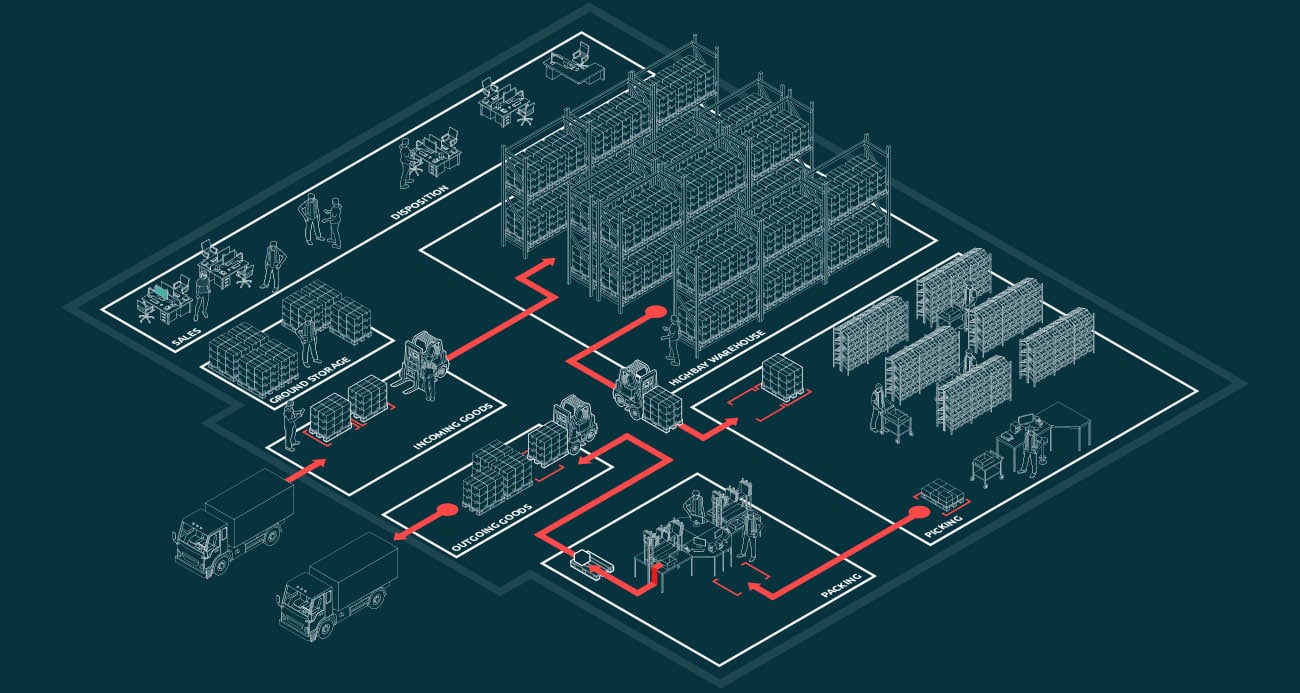

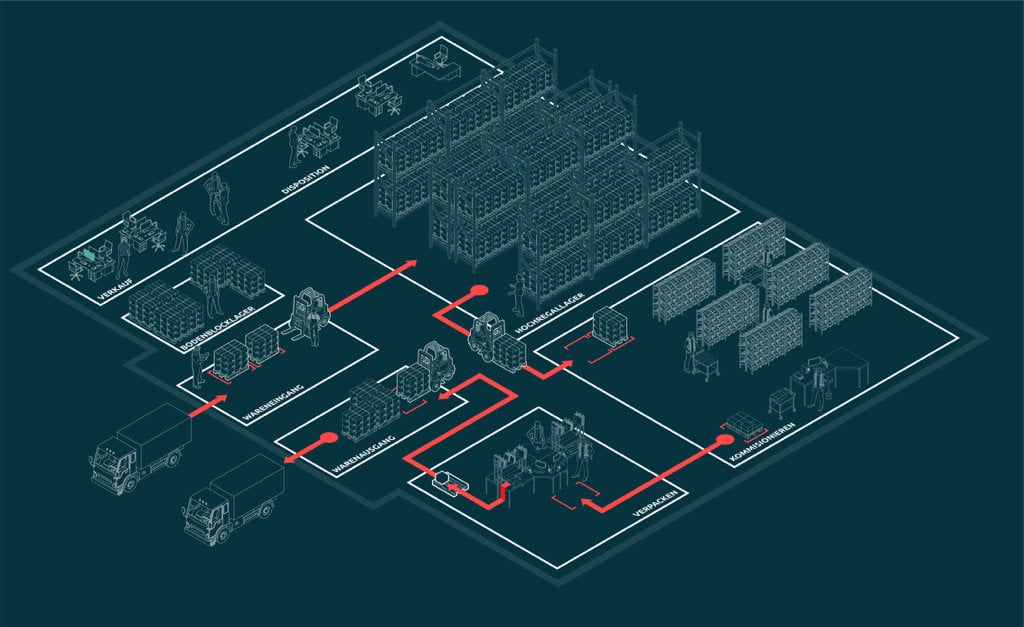

There are different types of warehouses, such as manually operated block storages, pallet shelves and shelves for item picking. Our standard solution is suitable for all common warehouse types that are operated by workers and forklift drivers with mobile barcode scanners. Automated systems such as conveyor systems or storage and retrieval machines are also supported, but require additional equipment. A very common warehouse layout is shown in the figure: Standard warehouse topology (see below).

This warehouse comprises

- an incoming goods area

- different shelves and floor storage areas for load units with load carriers (such as Euro pallets)

- shelves for order picking, suitable for items in boxes, mini-loads or items without load carriers, etc.

- workstations for packing goods for parcel services such as UPS, DHL, ...

- a dispatch area for outgoing goods to forwarders and carriers

Standard warehouse topology

What kind of processes does Bitergo WMS support?

All the main processes of a warehouse are supported. These are:

- Incoming goods

- Storage

- Order picking

- Packing

- Outgoing goods

- Stocktaking

- Inventory management

Each process has its own application for the web and as a mobile app. In addition to the main process, other apps handle supporting processes, such as

- Stocktaking

- Reports

- Mobile information

Which functions does Bitergo WMS support?

Short answer: all functions required for small and medium-sized warehouses, third-party logistics providers, e-commerce retailers and for the warehouses of manufacturing companies. These include:

- ASN (Advanced Shipping Notice) processing

- Support for any load carrier type

- Batch & serial number management for handling units

- Implementation of storage strategies that can be configured with regard to physical restrictions (height, weight, ...) or logical restrictions (item value, dangerous goods classification, ABC analysis)

- Storage of items in a cross-dock terminal, a standard warehouse or a bonded warehouse

- Efficient order picking processing (single order, multiple order, batch) taking into account different storage principles such as FIFO (First-In First-Out) or "Take the whole pallet"

- Support for different scanning and identification methods: Handling unit label, EAN or location barcode

- Picking and packing, printing of transport labels

- Scan consignment units for completeness, measure weight, print delivery note

- Permanent inventory counting and electronic stocktaking

wecare@bitergo.com

Phone: +49 231 878008-79

You are also welcome to use our contact form.

What is the difference between Bitergo WMS and other warehouse management systems?

Bitergo WMS stands for optimized warehouse management and paperless processes. The platform is operated as SaaS (Software as a Service) and consists of interconnected apps for web browsers and mobile apps for Android smartphones and barcode scanners. Compared to a conventional warehouse management system, this offers major advantages: Our ready-to-use apps generate a high degree of standardization while offering a high degree of flexibility. In fact, you simply select the right app for each use case that perfectly matches the operational workflow.

Data protection is very important to us. This is another area where we differ from most providers of warehouse management systems, as we operate our servers exclusively in German data centres.

Which apps are available?

The Web & Mobile App Master Data enables precise, valid and simple entry and maintenance of your master data (article, storage location, loading equipment and partner master data). All data can be entered either via an EDI interface, via CSV import or manually via the web interface. If your employee notices deviating data in the warehouse, this can be adjusted directly on site using the mobile app master data.

With the mobile app Goods Receipt (Android), you can quickly record incoming goods in the system. Handling units can be created against an advanced shipping notification or spontaneously. Barcodes, label printing and the creation of pallet labels are supported. A shipping notification can be received from the ERP system via the BSB interface or imported as an Excel/csv file.

The Mobile App Storage offers storage strategies for different warehouse types, such as block storage, rack storage or high-bay storage. In addition, specific restrictions are supported, such as pallet size, weight, fixed location assignments and/or freely definable classifications (e.g. ABC). Storage takes place to the second with the aid of a mobile barcode scanner.

Dispatch orders are received via a standard interface and displayed in the Picking web app. Next, the warehouse manager activates an order batch and creates pick lists for it. The picking app supports various strategies for this task, e.g. FIFO (First-In First-Out), expiry date, full pallet, multiple order, single order, single or two-stage, and offers a high degree of flexibility in controlling the picking process.

The Mobile App Picking guides the warehouse worker along the shortest route to the storage location and records the removal of items in real time by scanning storage location and/or item barcode labels. Item changes, replenishment and the consideration of unexpectedly empty locations enable extremely precise warehouse management. Picking ends at a packing or despatch station.

There are always reasons to move goods. With the Mobile App Stock Transfer, your goods can always be found. Stock transfer orders created directly in the mobile app or in upstream processes are processed by your employees in the warehouse and the new storage location is booked in the system after completion. This gives you full transparency of all goods movements at all times.

The repacking mobile app offers you flexibility in the utilisation of your storage space. Storage units can be split up or merged. By scanning the source and destination, the data is immediately updated in the system and you can always keep your pallets organised.

The Packing web app supports the packing of picked items into one or more shipping units. For packing, the app offers the Pick & Pack options and supports various workstation configurations with connected printers and scales.

The Shipping web app finalises the shipping order. Parcel labels and delivery notes can be printed. Optionally, shipping providers (e.g. DHL, UPS, Shipit Smarter, etc.) can be connected.

Finally, the shipping units are booked out of the system using the Outgoing Goods web app.

The Web & Mobile App Inventory enables electronic stocktaking and counting. This makes stocktaking processes simple, fast and minimises errors. Inventory management provides inventory reports in real time.

Additional apps such as the Mobile App Correction and the Web & Mobile App Information are suitable for efficiently dealing with everyday problems and make life much easier for operators.

What does Bitergo WMS cost?

With Bitergo WMS, you get a flexible and scalable warehouse management system that adapts to your specific needs. Choose from four pricing models – ranging from the free version for start-ups and small businesses to a fully customized enterprise solution designed to meet the most demanding requirements.

You can find a detailed overview of our pricing models here: https://bitergo.com/prices.

In addition to the included support services, you can also upgrade to one of our advanced support packages if your needs are more complex. A full overview of our support models is available here: https://bitergo.com/en/support.

How can I test Bitergo WMS?

How do I connect my ERP system?

For optimum performance, Bitergo WMS should be connected to your ERP (Enterprise Resource Planning) system if necessary. The ERP system is the superordinate system for managing article master data, customer orders and orders from suppliers. Warehouse Star is responsible for managing physical handling units and warehouse master data (e.g. shelf locations). The following message types are transferred between the two systems for synchronisation purposes:

- Article master data from the ERP system that is to be imported into Bitergo WMS. This is the basis for all operations!

- Advanced Shipping Notifications (ASN) from the ERP system to Bitergo WMS to indicate an expected goods receipt. After goods receipt, Bitergo WMS sends a receipt to the ERP system.

- Sales order from the ERP system. Bitergo WMS creates pick lists from this and confirms the order to the ERP system after picking or despatch.

- Bitergo WMS sends the correct available, reserved and blocked quantity of items to the ERP system so that it can synchronise its stock.

- Optionally, the blocked status of individual handling units can be transmitted bidirectionally (from the ERP system to Bitergo WMS or from Bitergo WMS to the ERP).

Does Bitergo WMS - Warehouse Star offer a REST API?

Which connectors are available?

SAP

Many customers operate SAP systems. That's why we have a ready-to-use connector to SAP WMS, eWM and Hana Cloud. The SAP configuration is carried out by your SAP department or your SAP partner. We also offer optional SAP consulting and realisation for this part.

weclapp

weclapp is a modern SaaS ERP system. We have a ready-to-use connector for connecting to the weclapp REST API.

E-Commerce

Warehouse Star integrates seamlessly with many webshop systems. Our e-commerce connector connects to:

- Shopware 5+6

- Shopify

- Magento 1+2

- WooCommerce

- XTCommerce

Forwarder & parcel service

When packing, before shipping, you may want to integrate the parcel service provider of your choice to create shipping labels and notify shipping units to the service provider. We offer ready-made connectors for:

- UPS

- UPS Express

- DHL

- DHL Express

- Swiss Post

- Trade fair shipments

...

What if I need a customized interface?

Our Customer Care Team will be happy to advise you on the implementation of new interfaces or connectors:

wecare@bitergo.com

Phone: +49 231 878008-79

You can also use our contact form.